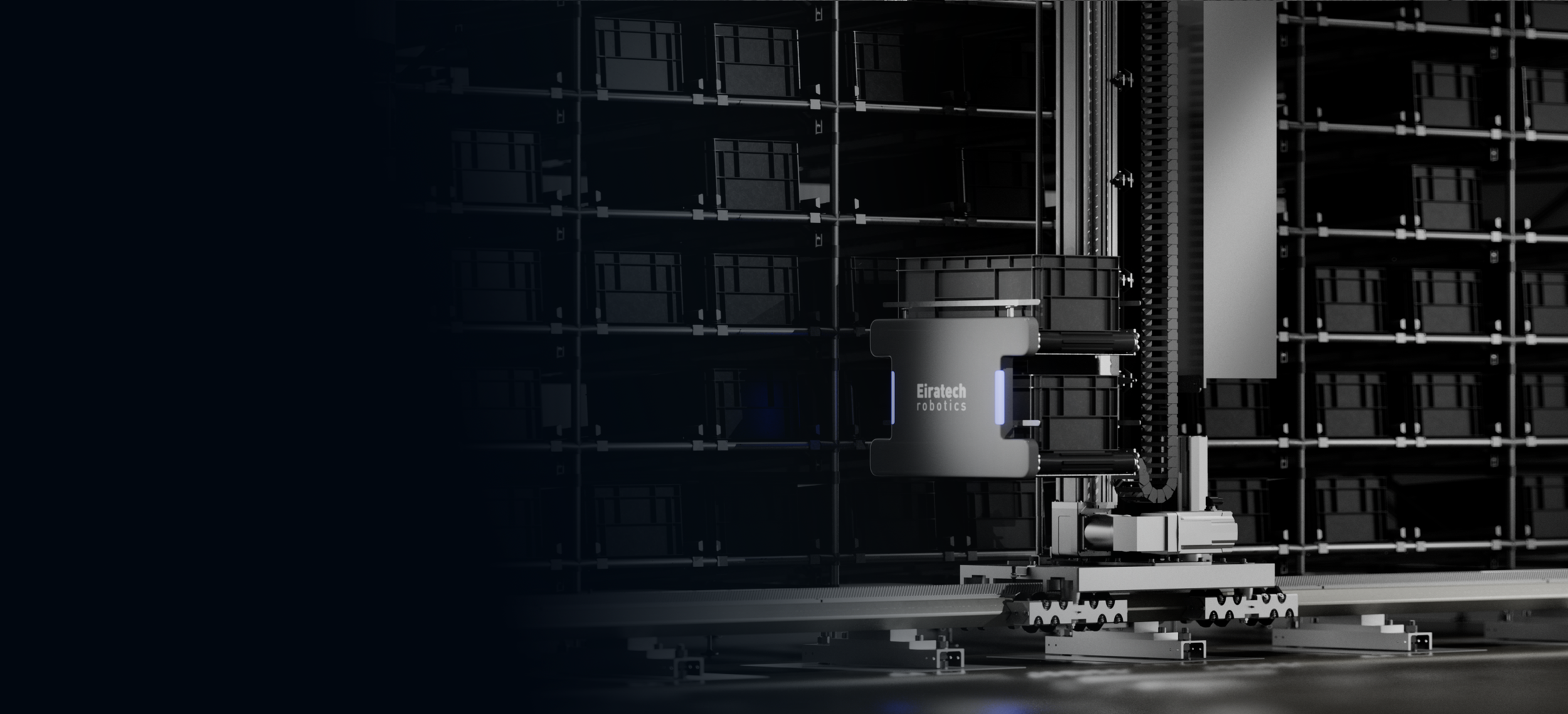

Case Study

Online Grocery

Fulfilment Store Picking

One of the leading grocery retailers in Europe

Realising the Vision for Online Grocery Fulfilment Automation

Eiratech’s solution is the missing link between picking and order fulfilment. It automates post-pick processes to boost capacity and lower costs without compromising store shelf space. The solution is flexible, modular, and easily customised to different store layouts, throughput

requirements, and temperature zones. It eliminates complexity and errors associated with high tote volumes and is cost-effective, saving up to 45% in labour overheads. The ease of installation and high reliability make it a robust solution for scaling in the grocery sector.

The Challenge

The primary objectives were to design, manufacture, install, and support a comprehensive post-pick order fulfilment solution operating in three temperature zones (ambient, chilled, frozen). This solution needed to integrate seamlessly with existing processes, linking the

retail shop floor's post-pick processes involving back-of-store consolidation, sortation, and van loading. It had to be achieved cost-effectively, within a limited timeframe, and be scalable for a large number of superstores.

The client faced significant challenges, especially after a major throughput boost during Covid that continued post-pandemic. Traditional solutions are expensive, require sufficient space, are time-consuming to install, and don’t fit specific requirements. Planning permission

to expand existing infrastructure was also time-consuming, and making structural changes was cost-prohibitive. The grocery industry is suffering from high wage inflation and a scarcity of resources in a tightening labour market. The automation solution needed to be

flexible, adaptable to individual store needs, and standardised for scalability, applicable to both supermarkets and dedicated fulfilment facilities.

Eiratech identified two key points for the design solution: linking the shop floor with a back-of-store automated sortation system to transport totes quickly, and utilising a 3D solution to capitalise on unused vertical space for automated storage, sortation, and consolidation.

The Objectives

Less than 10 minutes VAN load

Only 60 sq m allocated space

Threefold Increase in Capacity

Removes 93% of labour associated with staging, sequencing & retrieving totes

Labour Cost Savings: 25% per annum.

518 totes per hour turnaround capacity

Picking rate increased up to 350 picks per hour.

The solution

Turnround Station installed on the shop floor automatically unloading and loading totes in just 60 seconds.

LR21. Deposits and retrieves totes from overhead racking into a consolidation buffer.

Retrieval Robots: Eight robots, with an additional eight reserved for future scaling, transport two totes each by driving on overhead gantries.

EiraSky software. Manages the fleet of robots, automation layers, sensors, tote syncing, and final tote presentation for van loading.